Last week’s FABTech 2025 in Chicago was another dynamic showcase of what’s new—and what’s possible—in metal fabrication. With innovations on display, deep conversations with current and future customers, and a continued focus on simplifying tools and production, American Punch came away energized and inspired. Here’s a look back at some of the key moments, trends, and takeaways, along with how our standard ironworker tooling message played into everything we saw.

From Our Preshow Message to On-Site Reality

In our emails leading up to the show, we promised:

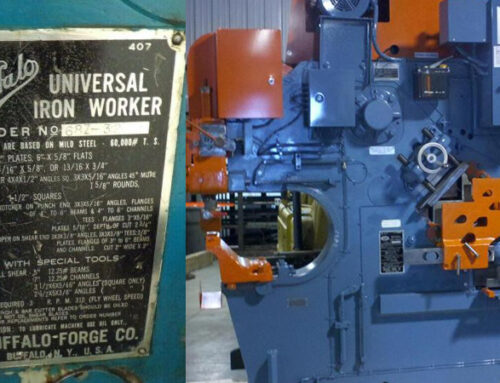

“One company. All your tooling needs. Less downtime. A simplified supply chain. From ironworker tooling, punches and shear blades to precision stamping components.”

That’s exactly what many visitors responded to. Across the booth floor, we found strong interest in tool sets that reduce operational friction. Whether it was standard ironworker punches & dies, heavy-duty shear blades, or precision stamping components like ball-lock and headed shoulder punches. Manufacturers want a partner who can cover the full range, deliver on time, and simplify their tool selection. That theme echoed throughout FABTech.

Highlights & Key Trends from FABTech 2025

From the broader FABTech event and updates shared via FABTech’s press releases and social media, here are some of the standouts:

- Largest exhibit floor ever. FABTech 2025 opened with the biggest exhibit hall in its history, featuring 1,700+ exhibitors. Innovations were everywhere, especially in automation, digital transformation, and tooling. Fabtech Expo

- Focus on automation, IIoT, and digital platforms. Technologies that help manufacturers do more with less—robotics, part-handling automation, cloud, software-enabled quoting and tracking—were major themes. These capabilities align with our goal of minimizing downtime and making tooling more dependable and predictable.

- Workforce education & inclusion. The 10th anniversary of the Women of FABTech program was celebrated, continuing the show’s commitment to workforce development and inclusion. Sessions on leadership, resilience, and tools to help newer entrants succeed were well attended.

- Encouraging sustainability trends. Across exhibitors, you saw efforts to reduce waste, improve energy efficiency, and adopt sustainable finishes and coatings. These fit well with tool designs engineered for longer life, better materials, and lower maintenance. FABTech 2025 Opens with Automation.

What We Saw at the American Punch Booth

At our booth, we saw these things clearly reflected:

- Strong interest in end-to-end tooling solutions. Many visitors wanted not just punches or shear blades individually, but an assurance that everything “plays nicely together”—ironworker tooling, precision stamping parts, custom dies. People appreciated that we cover that spectrum.

- Questions around lead time, quality, and reliability. Our conversations confirmed makers want tools that last, perform accurately, ship when promised, and reduce downtime. Precision tooling still commands respect, particularly when production tolerances are tight.

- Curiosity about how new technologies integrate with tooling. While our specialty is tooling, people wanted to understand how tools interface with automated presses, CNC systems, and even IoT monitoring. How does tooling need to adapt in settings with high-mix/low-volume, robotics, or real-time monitoring?

What’s Next: How We Respond

Based on what we heard and saw, here’s what we’re focused on delivering in the months ahead:

- Refining our product lines & support. Ensuring both our standard tooling (ironworker blades, punches, dies) and precision/stamping tool offerings like ball-lock and headed shoulder components are even more accessible. Better guidelines, clearer lead times, and stronger quality checks.

- Customer education & resources. Sharing more content—how to select the right tooling, maintain longer life, minimize stop-time and help customers plan with confidence when automation or changing production demands come into play.

- Expanding speed + custom capability. Faster turnaround on custom tooling, better inventory availability, and tools that are easier to integrate with automated systems.

Final Thoughts

FABTech 2025 proved once again that while tooling may be the backbone of fabrication, it’s how tools are delivered, supported, and integrated that makes the difference. The desire for fewer failure points, cleaner workflows, and partners who can manage everything from standard ironworker tooling to progressive stamping components came through loud and clear.

Thank you to everyone who stopped by our booth, shared feedback, and helped us see what the future of fabrication tooling needs. If we didn’t meet in Chicago, no worries, feel free to reach out as our team looks forward to helping with your tooling needs. We’re here for all your tooling needs. Call, email, or check out our new resources soon.