Ironworkers are a necessity in nearly every metal fabrication shop. These machines are essential to most shops. They are the preferred choice for punching, shearing, notching, coping, and bending. Additionally, they are used for many other fabrication processes.

With many add-on options for ironworker machines, it can be hard to know which machine is right for your shop. There are factors like price, ease of use, functionality and delivery that play important roles in the decision-making process.

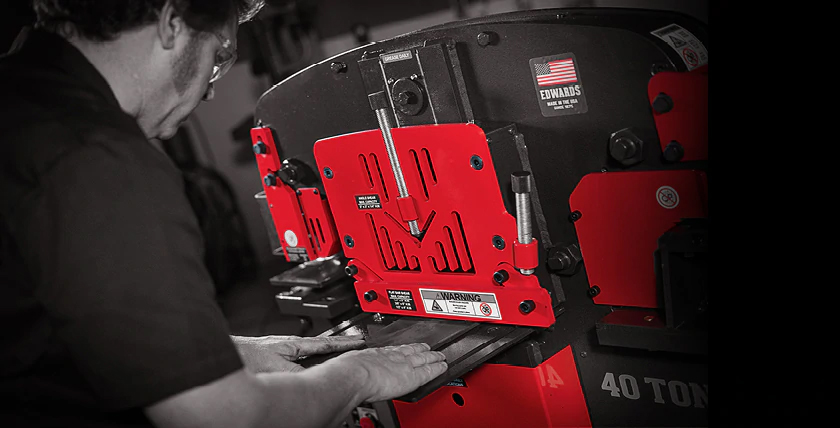

What Makes Edwards Ironworker Machines Unique

Edwards Ironworkers are versatile and durable machines designed for cutting, punching, notching, and bending various materials such as steel, aluminum, and brass. Edwards Ironworkers have a vast selection of tooling options. This makes them ideal for metalworkers and fabricators, as they can complete many fabrication tasks effortlessly.

In short, Edwards Ironworkers are an essential tool. Whether you’re working on a small project or a large industrial job, Edwards Ironworkers provide reliable and efficient performance to help you get the job done right.

Top Differentiators of Edwards Ironworkers

Top Differentiators of Edwards Ironworkers

Edwards ironworker machines are versatile and efficient tools that are widely used in metalworking applications. Some of the differentiators of Edwards ironworker machines are:

- Multiple Functions: Edwards ironworker machines are capable of performing a variety of functions, including shearing, punching, bending, and notching. This versatility makes them a popular choice for many metalworking applications.

- Power and Precision: Edwards ironworker machines are designed to be powerful and precise. They use hydraulics to provide a high level of force, which allows them to handle thick materials with ease. They also have accurate positioning systems that ensure precise cuts and bends.

- Easy to Use: Edwards ironworker machines are designed to be easy to use. They typically feature intuitive controls and quick-change tooling systems, which make it easy to switch between different functions.

- Durability and Reliability: Edwards ironworker machines are built to last. They are constructed from high-quality materials and are designed to withstand the rigors of heavy use. They are also backed by warranties and support from the manufacturer.

- Customization: Edwards ironworker machines can be customized to meet the specific needs of the user. They can be equipped with various accessories and options. Examples include different punch and die sets, gauging tables, and notching tools.

Overall, Edwards ironworker machines offer a combination of power, versatility, and ease of use that make them an ideal choice for many metalworking applications.

Top Industries Edwards Ironworkers Are Good For

Edwards Ironworkers are versatile machines that can be used in a wide range of industries. It makes them a popular choice for metal fabrication shops. These ironworkers are also excellent for cutting and punching metal beams and plates for framing, reinforcing, and other structural components.

The ability to shape metal parts and components is essential. Examples include brackets, flanges, and punching sheet metal for body panels. Additionally, cutting metal components for aircraft and spacecraft construction is necessary.

Edwards ironworkers are the workhorse in many of the top industries. Here is a list of top industries that Edwards Ironworkers are commonly used in:

- Metal Fabrication

- Construction

- Manufacturing

- Automotive

- Aerospace

- Agriculture

- HVAC

Overall, Edwards Ironworkers are versatile machines that can be used in various industries that require metal fabrication, cutting, and punching.

Common Edwards Ironworker Part Failures

Edwards ironworkers are heavy-duty machines that are designed to withstand the demands of metalworking operations. However, like any mechanical system, parts can wear out or fail over time for various reasons, such as heavy usage, improper maintenance, or manufacturing defects. Here are some common Edwards ironworker part failures:

- Hydraulic hoses: Hydraulic hoses are used to transmit fluid power to various components of the ironworker. They are subjected to constant pressure, bending, and abrasion, which can cause them to crack or burst, resulting in fluid leaks and loss of hydraulic pressure.

- Punches and dies: Punches and dies are made of high-strength materials. They can still wear out or break over time due to repeated use, improper maintenance, or damage from foreign objects.

- Shear blades: Shear blades are used to cut metal sheets or plates. They are subjected to high stress and friction, which can cause them to wear out, become dull, or even crack or break.

- Edwards ironworkers are fitted with electrical components like motors, switches, and relays. These parts can be affected by wear and tear, voltage imbalances, and environmental factors such as dust, humidity, and temperature extremes.

- Bearings: Bearings are used to support rotating shafts and reduce friction. They can wear out or become damaged due to insufficient lubrication, contamination, or overloading, resulting in increased noise, vibration, and reduced performance.

Regular maintenance is important to prevent or minimize common Edwards ironworker part failures. Replacing worn or damaged parts in a timely manner can extend the machine’s service life. This will ensure optimal performance and safety.

How to Keep Your Edwards Machines Running

Maintenance, spare parts and proper use are three of the most important factors in keeping your Edwards machines up and running. One of the most overlooked machine maintenance efforts for fabrication shops is proper machine and punch lubrication. Lubrication can help improve the life of punch and die tools. It reduces friction, lubricates the tool, removes heat, prevents scoring and avoids punch galling.

Having the right spare and replacement parts for your machine is also important when it comes to keeping your machine up and running. There are several Edwards ironworker parts that you should have in-house that include:

Our team of metal fabrication experts is continually looking for opportunities to improve production processes and reduce waste as well as ways to reduce wear and tear on your punches and dies. We know that every metal fabrication shop has its own unique challenges and opportunities. You can explore more reasons for punch failure on our site. And our team is here to help by improving tooling designs, production processes and more, contact our team for advice on your individual situation and needs.

If you have another brand of ironworker machine, American Punch has you covered there too. We stock a large inventory of punches, dies, shear blades and other tooling for the top brands in the industry. Check out tooling for your ironworker machine brand today.