When an American Punch customer realized it needed a design change, the request for special tooling came at the last-possible minute: The shop had already completed punching all 48,000 units for the project.

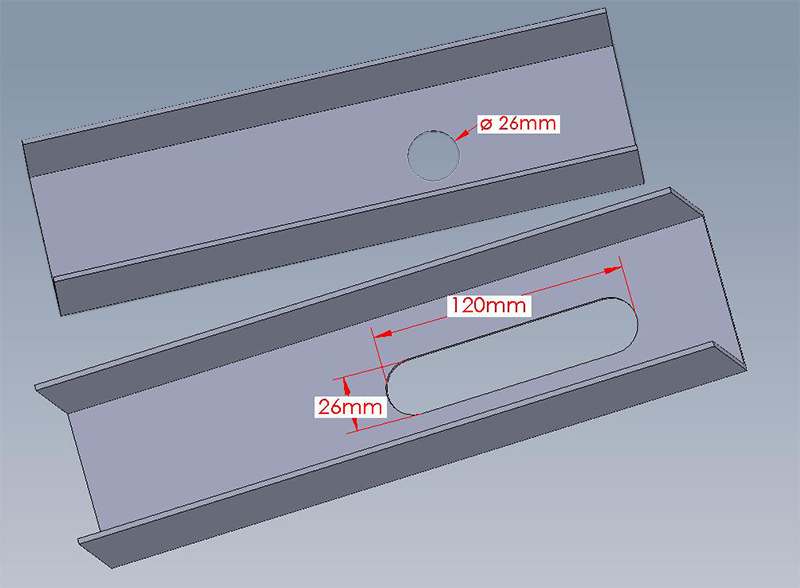

Only as assembly was about to begin, it became clear that the 26mm round hole indicated in the original print needed to be elongated into a 120mm slot. The situation was complicated because of the nature of the material that had been punched – a rolled channel made from high tensile steel.

But American Punch was able to design and manufacture tooling specific to the application that allowed the customer to re-punch the material accurately and quickly.

The bullet nose pilot of the punch we designed allowed the operator to easily and accurately align the punch to the existing hole without any worries about misalignment or overlapping holes. The convex shear punch face helped reduce the tonnage and the shock to the tooling.

In the end, the customer was able to quickly and efficiently re-punch all 48,000 pieces with the correct size and shape hole so that assembly could be completed with no loss of material.

As this incident illustrates, we can design and manufacture custom dies and punches to help our customers overcome their most difficult challenges. And we can help you design the special tooling you might need for your punching and metal fabricating operation.

We also carry a wide range of special tooling to meet unusual applications, including: